What are the preventive measures in the face of burner tempering?

For the burner, if the combustion rate of the mixed gas is greater than the ejection speed, a flashback phenomenon will occur.

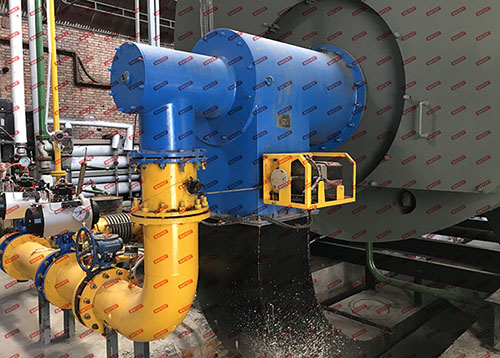

Difficult to de-fire, but easy to temper the burner, its combustion range will not be wide. For example, if the flame hole is relatively large, it is easy to temper, so it is more difficult to handle. To prevent flashback, the following measures are usually taken:

① Make the flame holes small and deep, you can choose to increase the number of flame holes, and the combustion rate of the gas near the hole wall is reduced by the cooling effect of the flame hole wall. Multi-nozzle burners, etc., all belong to this method.

②If the heat received by the burner head is conducted to the inside of the burner, the unburned mixed gas will be preheated by this part of the heat, so the burner head is made of ceramic materials with poor thermal conductivity, such as superheated burners, ceramic belt burners mouth etc. In the slot radiant burner, the whole burner head except the flame hole is covered with a layer of ceramic fiber, which can improve the thermal insulation effect.

③ Cooling is carried out at a distance from the furnace body in the burner head. Not only should the flame hole be small and deep, but also the burner head should be water-cooled or air-cooled, so that the cooling effect is greater. Usually, the burner head is 10~25mm away from the furnace body. When using a premixed burner on the furnace.

④ For the burner with sleeve fire, because the sleeve fire is first tempered, the flame hole of the sleeve fire is reduced (the slit is less than 1mm), and it is cooled to make the sleeve fire speed slightly lower, which is also good for preventing misfire.

⑤ When the primary air volume is reduced from 90% of the theoretical air volume to 70%, 50%, and 40%, the combustion rate is reduced from 70cm/s to 50cm/s, 20cm/s, and 10cm/s, so the primary air can be reduced by There are many examples in this regard by increasing the amount of secondary air to prevent tempering. When using a premixed burner on a furnace, in principle, the primary air ratio should be about 40%.

⑥If the injection speed is kept high, there will be no tempering, but in this case, the adjustment range of the combustion amount is narrowed. The internal pressure of the cup type radiant burner is usually above 25mmH2O.

⑦ The most fundamental measure to prevent tempering is to use a nozzle-mixed burner (that is, in the burner part, gas and air while mixing and burning).

The above is about the countermeasures for the burner tempering during work. If you want to know more about other knowledge, please pay attention to Zhengzhou Bona Thermal Energy Co., Ltd.