1. the conditions required to repair the burner

①. Intermediate or above electrician level, at least have an understanding of mechatronics equipment.Modern burners have a high degree of automation, such as the lack of sufficient electrician operation ability, in the electrical parts of the burners will be unable to start the inspection, but only limited to the general cleaning and disassembly.

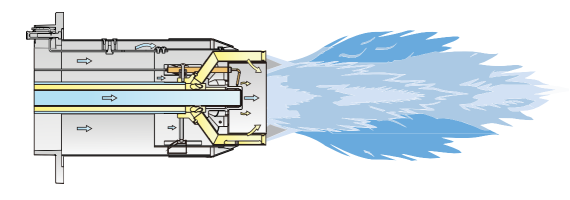

②. To simplify the understanding of the burner on the premise that the former has its own capabilities -- the burner is nothing more than a blowtorch.Compared with ZIPPO's gasoline lighter, the fully automatic burner simply has an electronic control system.

The burner is simply divided into three parts:

The control part,

The burning part,

Component part.

If you lack enough professional knowledge, you don't have to stick to various ways of classification, just according to their own understanding of classification.The main purpose of self-classification is actually to simplify maintenance thinking.(Do not refer to this article if you do not have the conditions described in article 1.)

③. If possible, it is better to make an appointment with a person with considerable professional experience to provide telephone support when necessary before self-maintenance.

2: necessary tools to repair burners

①. Electrical tools: one multimeter. If you do not have weak current maintenance ability, a multimeter worth 10 yuan is enough.

②. Mechanical tools: PH6 cross, one word screwdriver, disassemble and install general fixing screws;

③. Mechanical tools: PH2 screwdriver 1;

④. Mechanical tools: no. 12 adjustable wrench 1. Disassemble and install general fixing nuts or bolts.

⑤. Mechanical tools: one set of hexagon wrench (commonly used 2, 3, 4, 5, 6, 14), mainly used for dismounting oil pump and part of the main body of the fixing screws or bolts.

3.In the absence of experience in burner maintenance or even common sense understanding, it is recommended to adopt the method of troubleshooting.That is, under the premise of defining the main parts, one by one, clear the same, exclude the same.The following parts are commonly used:

4.: clear the main components and parts of the burner

①. Program controller, also known as combustion controller, or simply controller, program controller.Note that not all burner controllers are program controllers and a small number of burner controllers are applied with sequential controllers.

②. Ignition transformer, referred to as igniter, commonly known as high voltage bag.

③. The damage frequency of oil pump and moving components, such as fuel quality beyond the use range, cannot be estimated.In recent years, the frequency of oil pump damage is relatively high.

④. The nozzle is washed by high-pressure fuel for a long time, close to consumable.Its life is also affected by fuel quality.

⑤. Photocell, including a part of flame monitoring element made of photoresistor.Commonly known as the electric eye, will also be referred to as the general flame monitor.For other items not listed, see Expertise: Burner Accessories and related content.

5: using the elimination method to repair the fuel burner in accordance with the principle of simple to difficult, item by item screening, if there is no enough experience, do not from difficult to easy.

①. Visually, the whole machine has no difference in appearance.

②. Power supply: it is important to confirm the access end of the power supply of the whole machine and the burner controller.Firstly, the power supply of the whole machine is defined, and then, when the power supply of the whole machine is connected, the controller power supply is confirmed to be connected normally.Under the condition that the power supply of the whole machine is normally connected and the controller has no power voltage, personnel with the ability of electrician operation shall check the circuit.This step may be omitted if it is clear that the power supply is correct, for example, the burner can start normally and only the combustion is interrupted abnormally.If the burner fault shows that the whole machine has no action, it must be checked.

③. Under normal pressure of fuel supply, check the pipeline from the oil tank to the oil pump. First, visually observe the fuel reserve status of the oil tank, and then unhook the connection between the oil pipe and the oil pump to see if there is any fuel flowing out....(Poor fuel flow can cause smoke and intermittent shutdown of burner, etc.)The following requirements require a certain level of electrical operation ability, including mechanical and electrical equipment maintenance experience.When the first three points are clearly defined as normal, the fault state of the burner is mostly after the start of the burner motor: (1) no ignition, (2) short time after ignition, (3) irregular interruption of the combustion midway, (4) smoke....Of course also includes in the power supply, fuel under normal circumstances, the whole machine does not act.

④When the power supply of the whole machine and the controller is connected normally, this phenomenon occurs. After the program controller is reset, there is still no action, and most of them are damaged by an important part.(1) with the screwdriver rotary motor rotor shaft on the word slot, remove the mechanical fault of the motor.(2) Measure the motor coil, if it is a single-phase motor, check the starting capacitance, three-phase motor check the power relay and thermal relay.(3) Switch on the motor power separately, the actual observation shows that the above are normal, then the motor fault is eliminated.(4) Measurement of photocell, photocell can be generally measured by a multimeter to determine, usually, only the measurement of its light and light state on and off can be, without considering its accurate resistance value.Generally speaking, if the whole machine has no action, the photocell can only cause this phenomenon under the condition of normal operation.Measuring the ignition transformer (), connect the igniter separately, visually observe the actual ignition position (need to remove the burner). The above inspections are all normal, and most of them are failures of the program controller.The controller is more complex and there is no simple method to judge it.If the weak current maintenance ability is not available, the controller can only be replaced for testing.

⑤ Don't ignition burner motor start up, did not close the ignition in a short period of time, more for ignition failure, including a little firearm damage, and ignition position is not correct, such as flint position deviation, or electrode leakage, etc.) after start-up, briefly closed after burning, much as the photocell fault, including phototube photosensitive disorders or not after sightseeing conduction, the project should be finished in the 4) (4) screen.In the above phenomenon, the possibility of output fault of the controller cannot be ruled out. For example, it can be checked in the operation process of the burner if the electricity is better.

⑥. Smoke under the premise that the moving parts are in good condition, adjust the oil pressure and throttle Angle properly.Note: If not quite sure, do not adjust the pressure and Angle at a large Angle.(2) Check the smoke exhaust system such as combustion chamber and chimney, visually observe whether there is oil scale.Under the condition of high temperature, volatilization of oil scale is one of the important causes of black smoke.If the above two steps are not effective, do the following work:

Check the filter, including external filter, oil pump filter (oil pump), nozzle filter, etc.Check oil pump pressure and adjust appropriately.If the pressure is lower than 1mpa, most oil pumps need to be replaced.If necessary, disassemble the burner and observe the fuel injection status.The oil pump pressure adjustment is normal, the nozzle can be used more, but it is recommended to replace the nozzle once a year -- even if the nozzle wear does not affect the use, but the combustion efficiency will decline with the degree of wear.If no fault source is found after the above investigation is completed, personnel with professional experience should be hired to re-check the ratio of air combustion.Burner smoke, it is very simple, just the throttle oil pressure can be solved.But in fact, it involves the core combustion technology of the burner, so it is quite complex, and some of the burner smoke failure is professionals can not solve, but can only take the way to replace parts to deal with.

Abnormal interruption abnormal interruption, involving more objective factors, the need for a comprehensive analysis of the working environment.