When the furnace aluminum is melted, from tapping liquid to loading new aluminum, a long open flame should be kept burning at all times, and the blower and induced draft fan should be in operation. Should not be closed. If the blower and induced draft fan are turned off, it will inevitably cause the fuel quick cut valve to close interlock. You need to restart the blower and induced draft fan, and re-ignite to enter the baking.

Always pay attention: whether the fuel pressure, air pressure, and compressed air pressure are normal. Find the problem and solve it in time.

Always pay attention to: fuel quick cut valve, fuel regulating valve, air regulating valve, flue gas regulating valve, photoelectric detection device, blast

0 Whether the machine and the induced draft fan are working properly. If the problem is found, solve it in time according to the burner maintenance guide.

The main problems existing in the channel type regenerative heating furnace

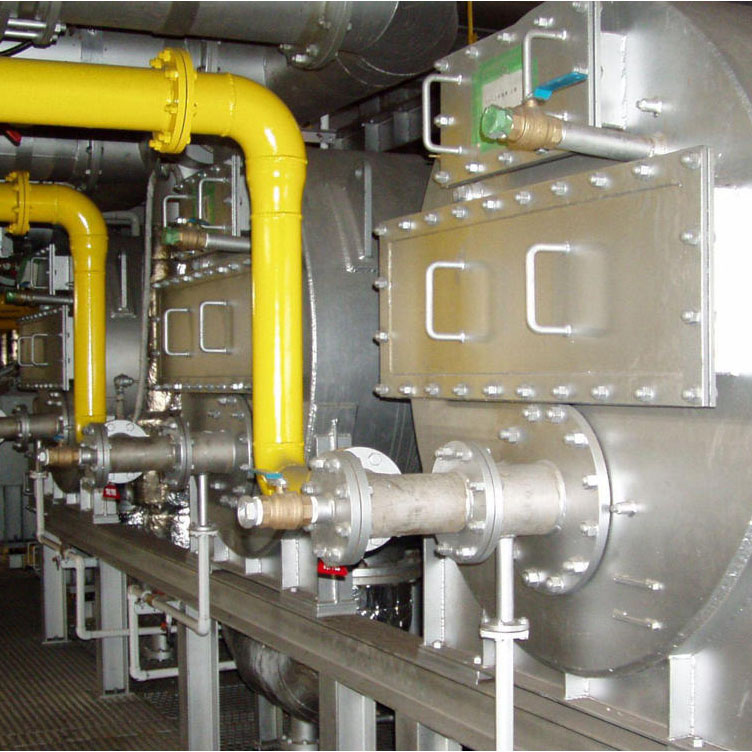

1. The high-temperature flue gas, high-temperature air, and high-temperature gas of the channel type fan heating furnace above 1000°C are transported by refractory materials on the wall of the furnace. Due to the limitations of the performance, construction, baking, and life of the refractory materials-a series of problems, there are hidden dangers of unsafety after the heating furnace is put into use

2. The channel type regenerative heating furnace has no regenerative burner. The cold furnace starting range is less than 700°C and the low temperature state can not burn stably, so it is difficult to accurately control the temperature to 500~650°C in the low temperature section, and the cold furnace startup depends on the installation of many conventional burners, the system is complicated and the furnace rises. long time.

3. The channel-type regenerative heating furnace cannot adapt to the combined use of multiple fuels or the need to alternately change fuel varieties. When the company wants to change the fuel structure, the investment in the furnace transformation is close to the investment of a new furnace o4, the upper part of the channel-type regenerative heating furnace , The lower heat load is difficult to adjust, and the furnace temperature can only be adjusted manually or automatically in sections, and cannot be adjusted to the manual or automatic adjustment of each burner (or each heating point), which makes the heating of the billet In order to ensure the quality, especially the heating quality of alloy steel.

5. The area of the channel type fan heating furnace is too large.

06. For the transformation of the old furnace, the channel-type heating furnace must change the furnace foundation, column, steel structure, large investment, and construction

Long period and six degree of elegance in construction.

7. The fan heating material "ceramic pellets or honeycomb body" of the channel heating furnace is inconvenient to maintain.

8. The channel type fan heating furnace is elegantly equipped with a slag outlet at the bottom of the furnace.

9. For the high calorific value gas above the mixed medium gas (1800 kcal/m3), the channel type regenerative heating furnace adopts double preheating air and coal gas. Since the heating value of mixed gas is much higher than that of blast furnace gas, once it leaks in the furnace wall, the burning temperature of high heating value gas is much higher than that of blast furnace gas. Therefore, the damage to the furnace wall is fatal, and there may even be a big hidden danger of insecurity.