Main points of the development of coke oven gas industrial burners

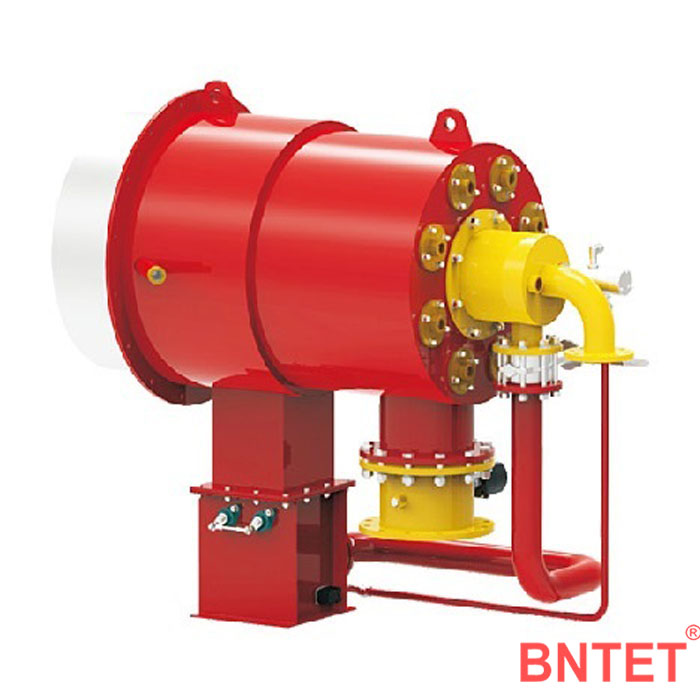

The coke oven gas industrial burner is a special device for heating facilities (such as boilers, industrial furnaces, etc.) that uses hot gas as a heat source to realize the hot gas combustion process. The main function is to introduce the hot air and combustion air into the heating facility to burn or burn in the burner according to a certain proportion and certain mixing conditions, and to meet the requirements of the direction, shape, rigidity and spread of the flame. During the heating process. The coke oven gas industrial burner is designed for the blast furnace exhaust gas produced by iron and steel enterprises. Coke oven gas industrial burners use blast furnace waste gas with any pressure and any calorific value to achieve automatic ignition and other functions.

Key points for the development of coke oven gas industrial burners:

Coke oven gas industrial burners use blast furnace gas instead of coke oven gas and are equipped with safe burners. Through the analysis of blast furnace gas combustion characteristics data, the following conclusions are drawn: The disadvantage of blast furnace gas is poor combustion stability and easy flameout. Therefore, in the process of developing coke oven gas industrial burners, how to ensure the safe and effective use of blast furnace gas is the key.

CO is the main combustible component in blast furnace gas, accounting for more than 90% of the combustible component. It is a colorless, odorless, and toxic gas with a high degree of danger. Since the ignition temperature of blast furnace gas is higher than that of coke oven gas, the ignition concentration range is narrow. Once pressure fluctuates, the coke oven gas industrial burner will catch fire, causing flameout of the furnace and gas leakage, leading to major safety accidents. Therefore, preventing flameout is the key to this technology. Through the analysis of the combustion characteristics of blast furnace gas, in order to prevent the burner from extinguishing, the necessary conditions for blast furnace gas combustion are as follows:

(1) The relative concentration of air and gas must be appropriate and within the specified range.

(2) Control the average gas velocity at the outlet of the coke oven gas industrial burner within the combustible range.

(3) Preheat the gas, make the gas temperature close to the ignition temperature, easy to catch fire.

(4) Set a duty flashlight (dimmable) at the exit of the coke oven gas industrial burner as the ignition source.