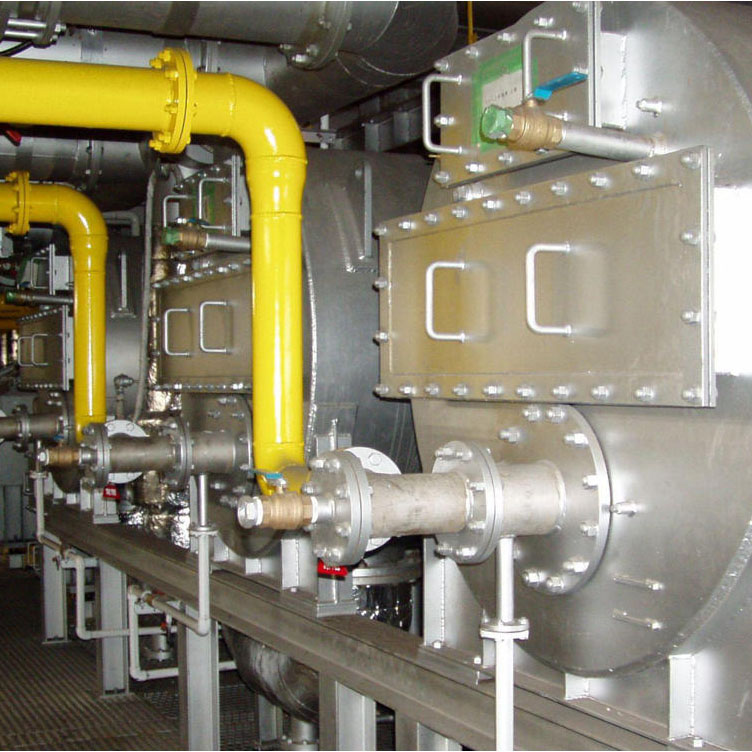

Industrial regenerative burner factory manufacturers

The working principle of the regenerative burner is that the room temperature air from the blower is switched into the regenerative burner B by the reversing valve, and is heated when passing through the regenerative burner B ceramic ball, in a very short time The internal room temperature air is heated to close to the furnace temperature (generally 50-100°C lower than the furnace temperature). After the heated high-temperature hot air enters the furnace, it entrains the flue gas in the surrounding furnace to form a stream with an oxygen content of much less than 21% At the same time, the fuel is burned in the oxygen-poor (2-20%) state; at the same time, the hot flue gas after combustion in the furnace of the regenerative furnace burner passes Another regenerative burner A is discharged into the atmosphere. When the high-temperature hot flue gas in the furnace passes through the regenerative burner A, the sensible heat is stored in the regenerative burner, and then passes through the low-temperature flue gas below 150℃ The reversing valve discharges. The reversing valve with low operating temperature is switched at a certain frequency, so that the two regenerative burners are in the alternate working state of heat storage and heat release, thereby achieving energy saving and reducing NO2 emissions. The commonly used switching cycle is 30 -200 seconds. Regenerative burners are widely used, and are mostly used in aluminum melting furnaces, iron melting furnaces, steel melting furnaces, and lead melting furnaces. Regenerative burners are non-standard customized burners, and customized solutions can be designed according to requirements!