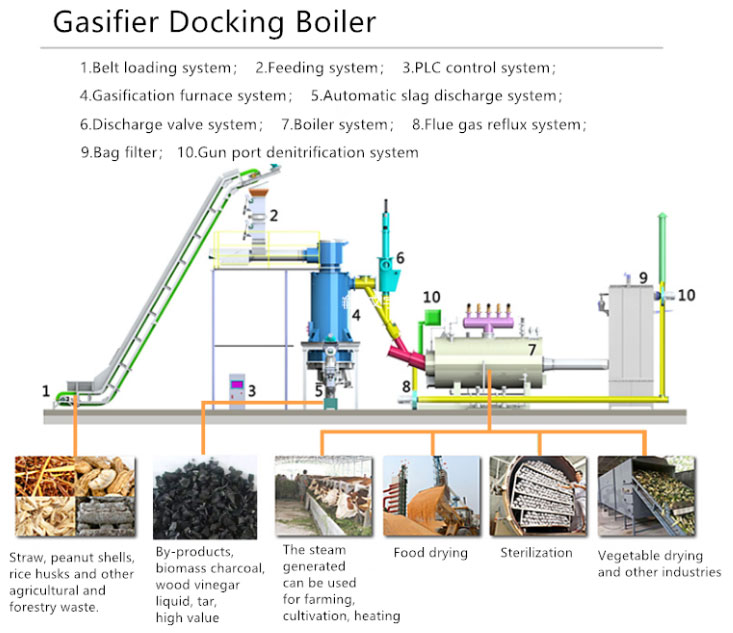

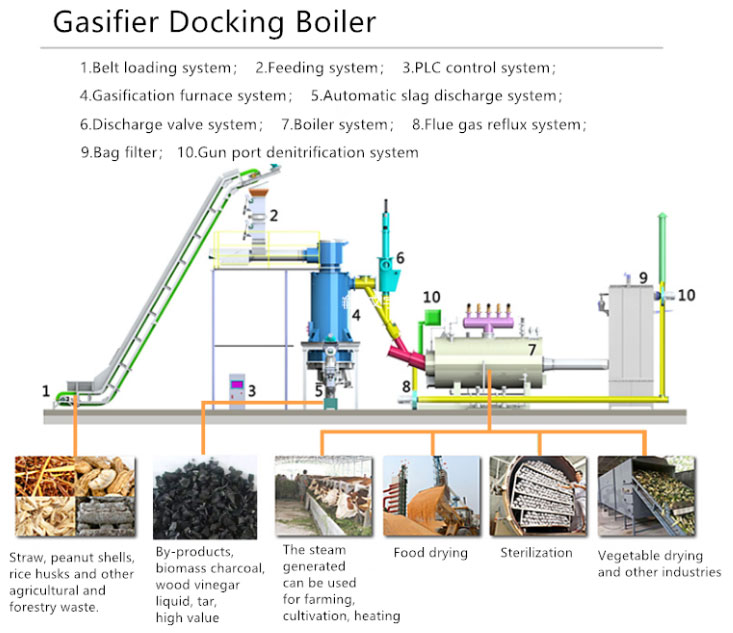

Description of Biomass Gasifier

A biomass gasifier that uses biomass such as straw and corncobs discarded in rural areas as the main fuel to achieve environmental protection effects.

The biomass gasifier can heat the biomass raw material under the condition of incomplete combustion to crack the organic hydrocarbons with higher molecular weight into combustible gases such as CO, H2 and CH4 with lower molecular weight.

Product Structure

1) Feeding and conveying equipment:

The feeding and conveying equipment chooses a belt conveyor with stable performance.

2) Storage bin:

The storage bin can store fuel for 6 hours to ensure continuous production.

3) Feeding screw feeder:

The feeding screw feeder is controlled by a speed-regulating motor, the feeding is stable, and the feeding amount can be adjusted according to the boiler load.

4) Gasifier body:

The main body of the gasifier is the core equipment of the whole system. The biomass solid fuel is pyrolyzed and gasified in the main body, and transformed into high-temperature biomass gas.

5) Fan:

The fan provides the air required for the high-temperature gasification of the bulk biomass.

6) Automatic control instrument:

The automatic control instrument is the control nerve of the whole system, which is used to control normal operation, production tracking, and fault alarm analysis.

7) Cyclone dust removal equipment:

Used to treat biomass gas to ensure clean gas entering the boiler/kiln.

Requirements: Specification: 30mm-100mm, moisture content<20%.

Used to treat biomass gas to ensure clean gas entering the boiler/kiln.

Combustion Fuel

Straw, sawdust, wood scraps, grain husk, rice husk, sawdust, etc.Requirements: Specification: 30mm-100mm, moisture content<20%.

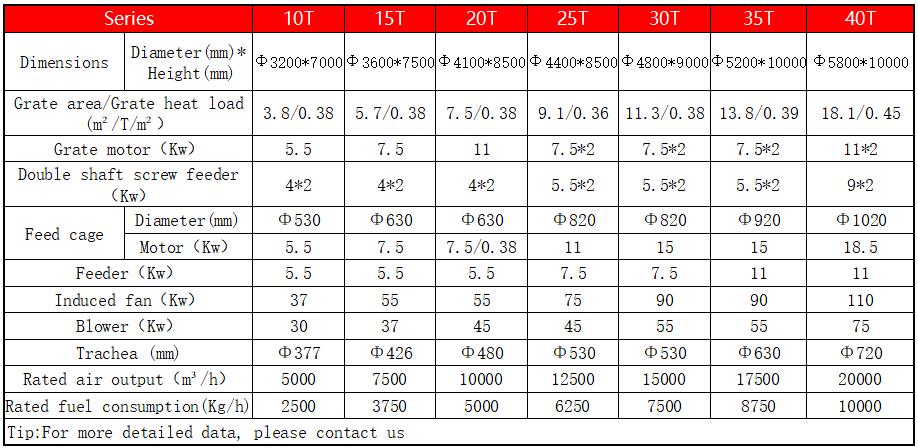

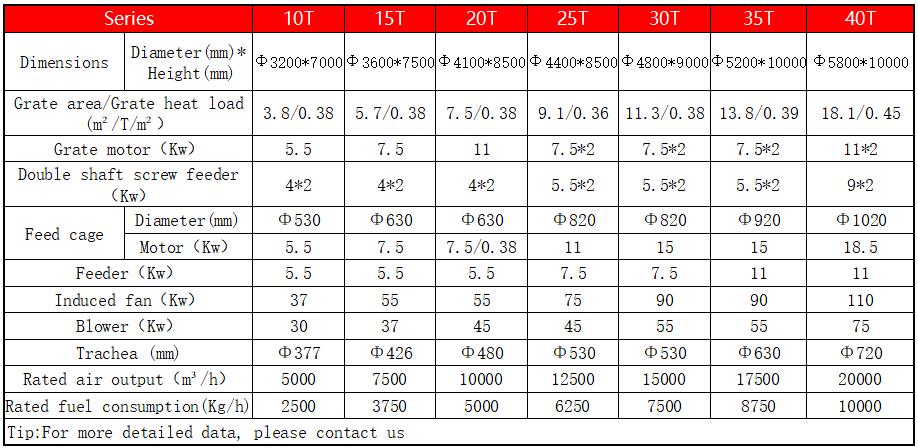

Product Parameters

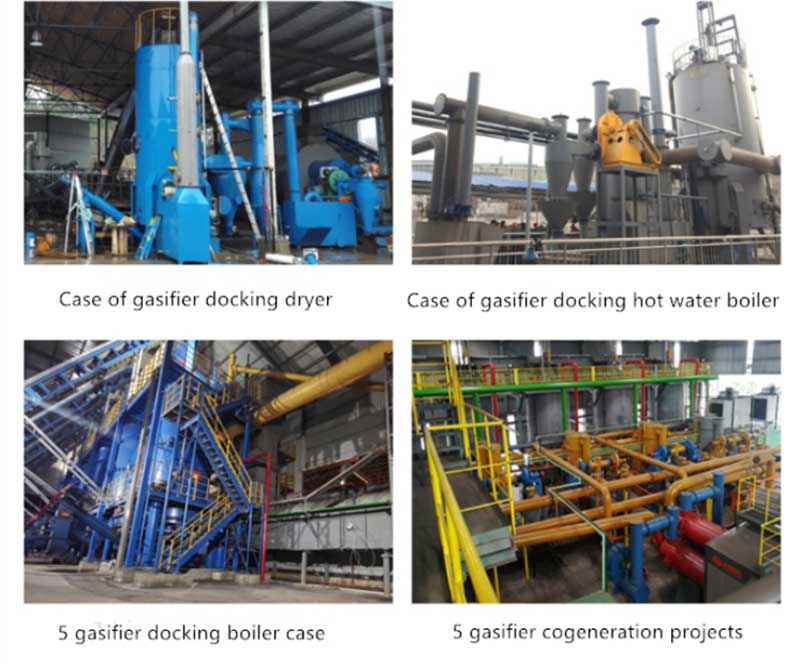

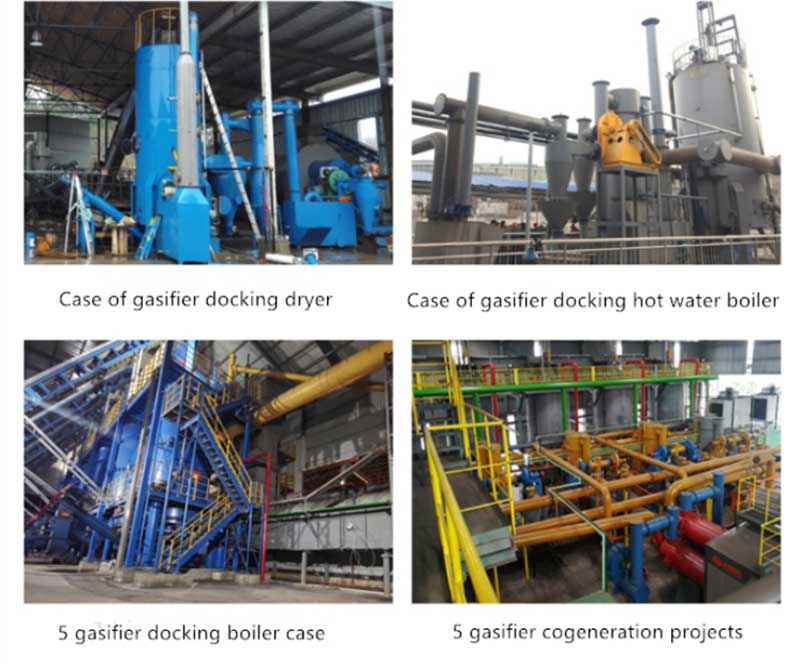

Related Case