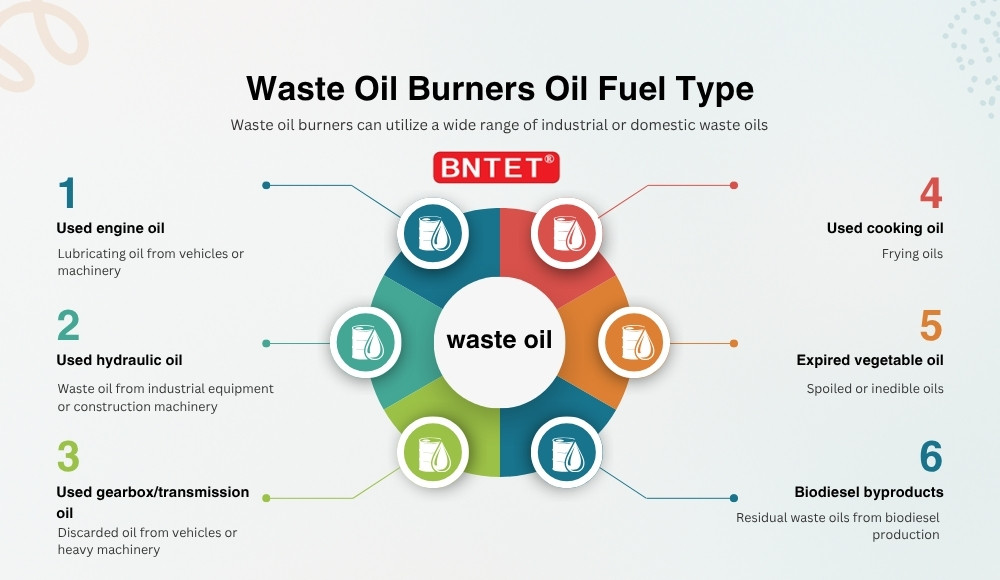

Waste oil burners provide an efficient solution for repurposing discarded oils as fuel. These systems can process various types of waste oils, offering both economic and environmental benefits. Below is a comprehensive guide to suitable fuel options and key operational considerations.

1. Mineral-Based Waste Oils

Used Engine Oil: Spent lubricants from automotive and industrial machinery (requires filtration)

Hydraulic Fluids: Discarded oils from heavy equipment and manufacturing systems

Transmission/Gear Oils: Waste lubricants from drivetrain components

Metalworking Fluids: Coolants and lubricants from machining operations

2. Plant-Derived Waste Oils

Recycled Cooking Oil: Post-consumer frying oils from restaurants and food processing

Degraded Edible Oils: Rancid or expired vegetable oils (soybean, canola, palm, etc.)

Biofuel Production Waste: Residual oils from biodiesel manufacturing

3. Specialized Waste Streams

Petroleum Sludges: Bottom sediments from storage tanks and refineries

Asphalt/Tar Products: Heavy residues from paving and roofing operations

Marine Fuel Residues: Waste oils from ship engines and bilge systems

Critical Operational Factors

Fuel Preparation Requirements

Filtration: Essential for removing particulates and extending equipment life

Dehydration: Water content should be minimized to prevent combustion issues

Viscosity Control: Heating may be necessary for proper atomization of heavy oils

System Compatibility

Different burner designs accommodate specific oil characteristics

Material selection must account for potential corrosive elements

Environmental Compliance

Emission control systems may be required depending on fuel composition

Local regulations often dictate permissible waste oil categories

Unsuitable Materials

Volatile Petroleum Distillates (e.g., gasoline, solvents)

Chemical-Contaminated Streams with unknown composition

High-Halogen Content Oils that may produce toxic combustion byproducts

Implementation Note: Prior to use, verify equipment specifications with the manufacturer and ensure full compliance with applicable environmental regulations. Proper fuel characterization and system maintenance are essential for safe, efficient operation.

This revised version improves technical accuracy, enhances readability, and organizes information more effectively for professional users. The content maintains all key details while presenting them in a more structured format.