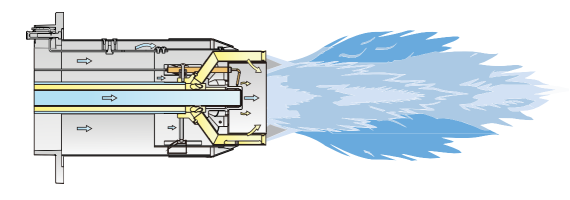

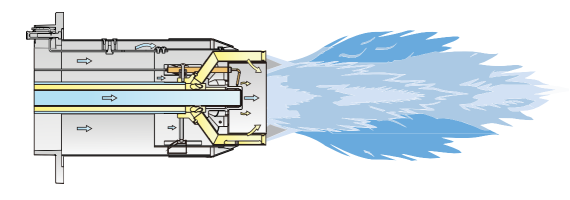

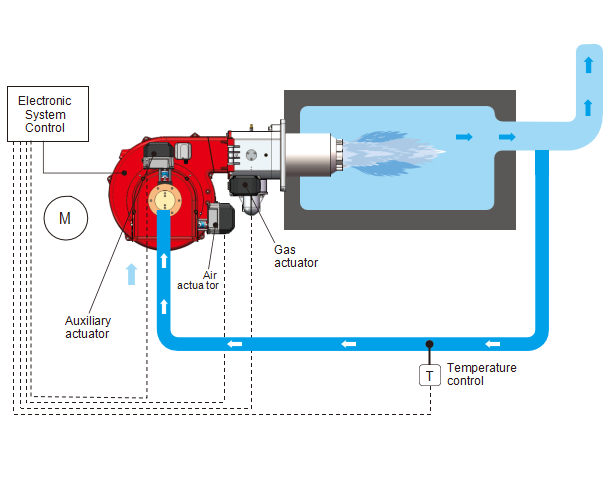

FGR Flue Gas External Cycle Combustion Technology

Bntet FGR flue gas is burned in an external cycle, and part of the flue gas is mixed with air and sent to the combustion chamber for combustion. The combustion air after mixing can effectively reduce the temperature and oxygen concentration in the combustion chamber.

The combustion reaction activation energy of gas and oxygen is much less than that of oxygen and nitrogen, so the gas first reacts with oxygen.When there is surplus oxygen, the gas reacts with nitrogen to form NOX. However, the reaction with nitrogen becomes very slow due to the low reaction zone temperature, which effectively inhibits the formation of thermal NOX.

Safety And Environmental Protection

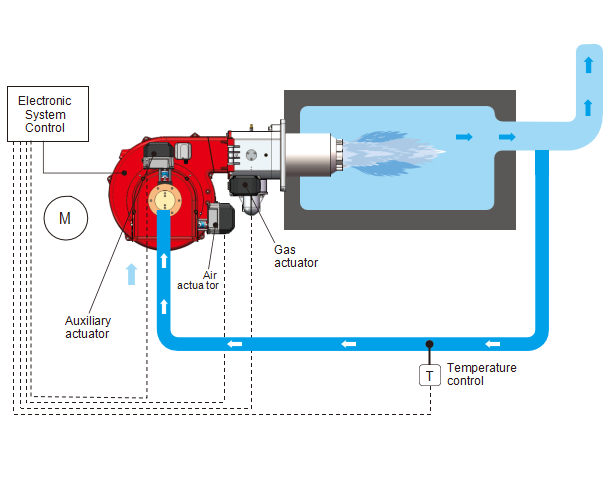

BNG…FGR series burners achieve optimal air/gas mixing with their unique design, effectively reducing pollutant emissions.

The gas in the combustion head is ejected through the hole in the combustion head, perpendicular to the air flow;A portion of the fuel is sprayed directly into the center of the flame.Low temperature flame combustion can prevent the formation of NO.The steady combustion of the flame prevents the high oxidation reaction inside.

The high flow rate of air when it leaves the combustion head accelerates the recycling of combustion gas, which can further reduce emissions.The emission of pollutants from this series of burners is below the most stringent emission standards.