Description of Eclipse High Speed Burners

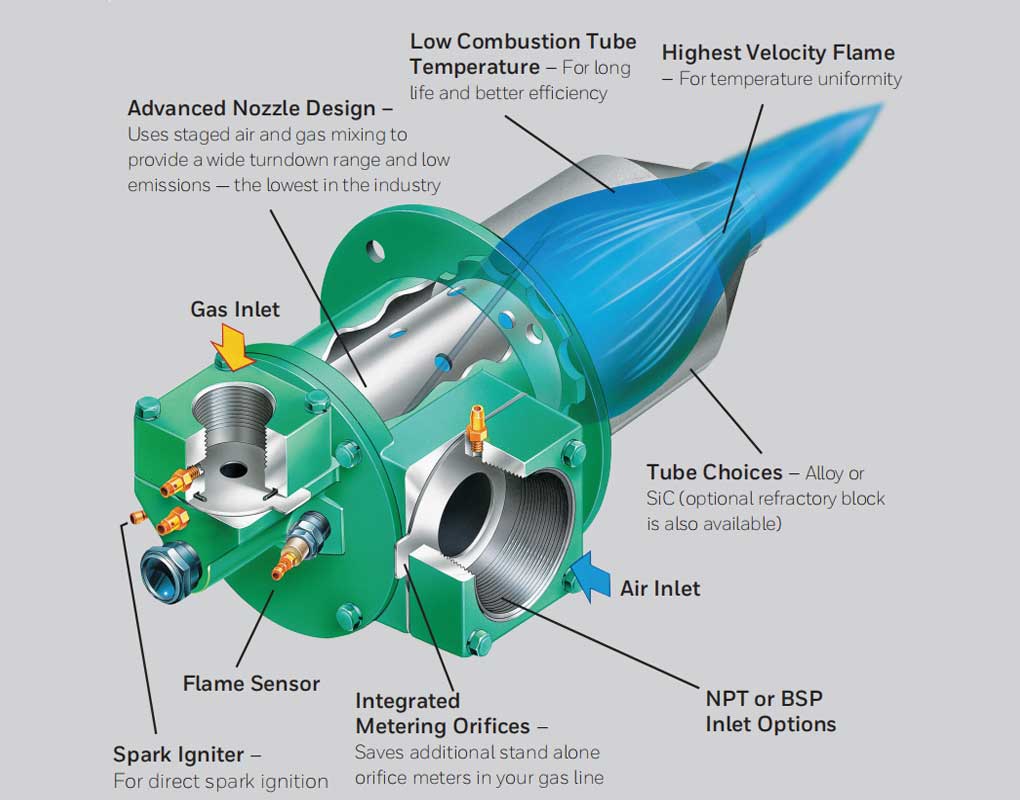

BNTET Eclipse ThermJet High Speed Burners feature the highest flame velocities available.

Comparison tests show that ThermJet delivers the lowest emissions of any competitive model. Integrated gas and air orifices simplify burner piping, set-up and adjustment. Air and gas inlets are independently adjustable in 90-degree increments to suit a variety of piping alternatives.

Working Principle of Eclipse High Speed Burners

The ThermJet high-speed burner can completely burn the fuel with super high heat load.

The volume of the combustion chamber of the burner itself is small, and the fuel can be basically completely burned in it, so the volume heat intensity of the combustion chamber is very high.

At the same time, due to the high flow rate of the combustion gas, the convective heat transfer can be enhanced, and the uniformity of the furnace temperature can be improved.

Studies have shown that when the furnace temperature is between 850 and 1150°C, the temperature difference is 7°C.

The atmosphere in the furnace is easy to adjust to oxidizing or reducing, and stable combustion can still be achieved when the excess air coefficient is high.

The excess air volume can reach 50.0, which is much higher than the 2.5 of ordinary burners.

The combustion air temperature of the high-speed burner can be adjusted freely within the range of 200~1800℃ (excess air coefficient α is between 1~50) by adjusting the primary and secondary air and gas volume, so that the high-speed burner can adapt to various kilns.

To improve the quality and output of products, high-speed burners can expand the scope of use of kilns.

Application of Eclipse High Speed Burners

• Hardening furnaces

• Tempering furnaces

• Non-ferrous melting

• Reheating furnaces

• Fluidized bed driers

• Thermal oxidizers

• Preheated air.

• Ladle/tundish

• Glass lehrs

• Environmental applications

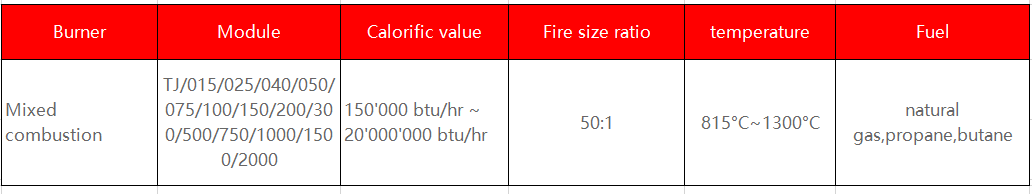

Data of Eclipse High Speed Burners