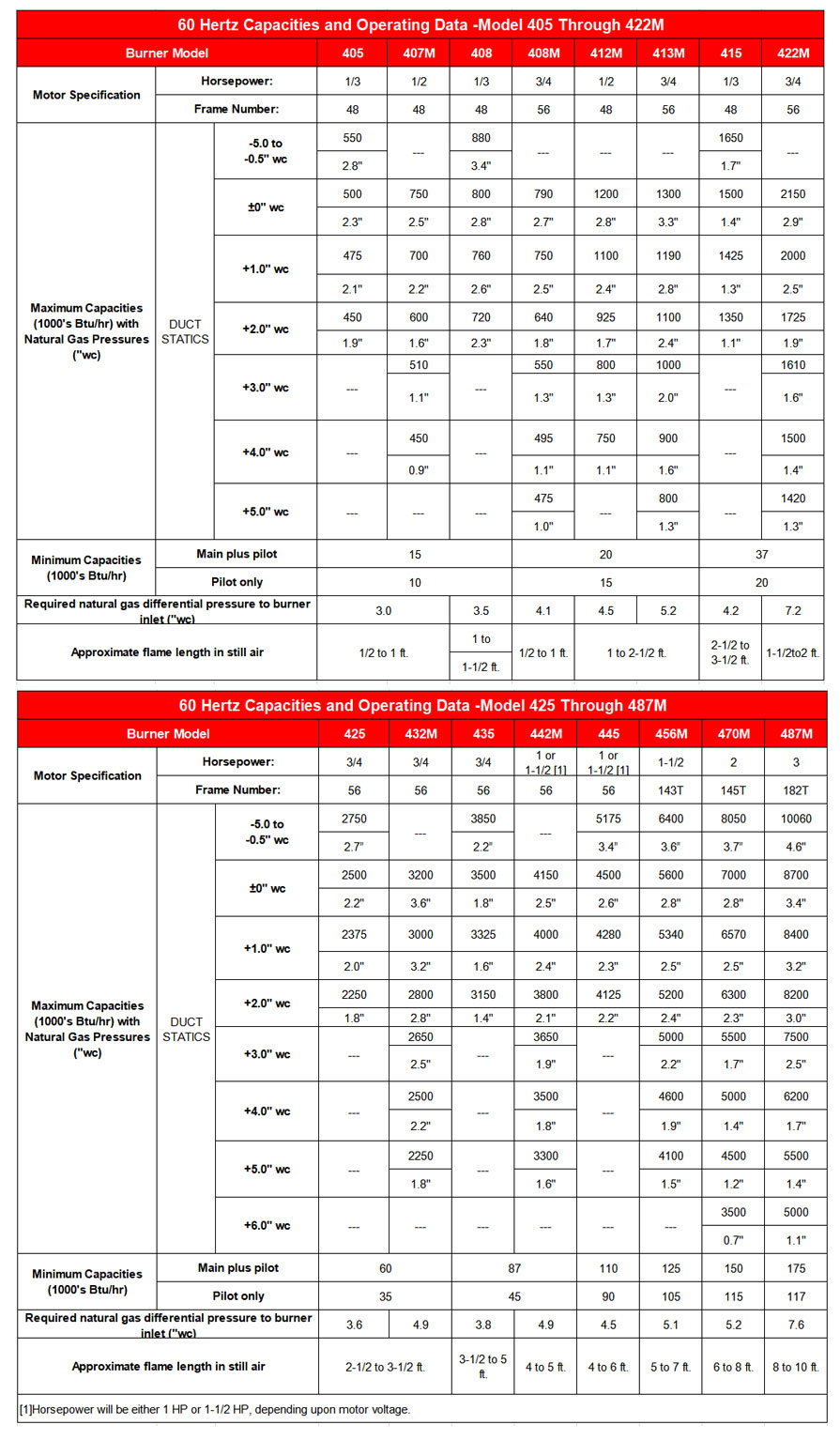

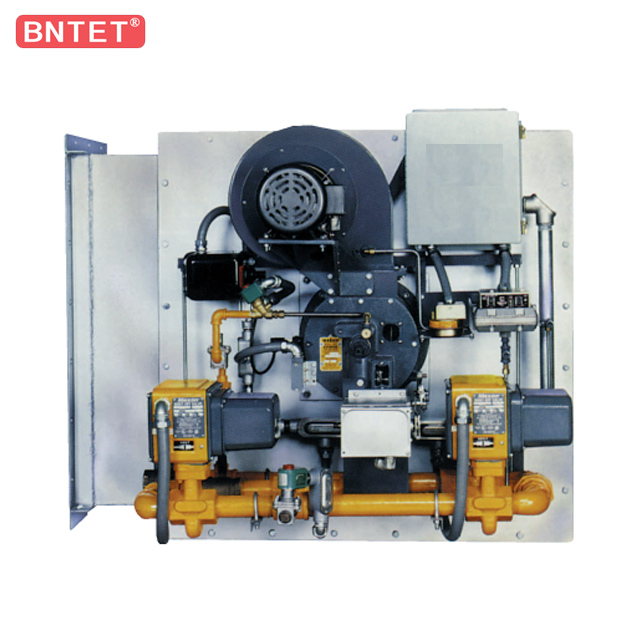

PACKAGED HEATER/DUCT SEC- TIONS FOR PRE-ASSEMBLED OVENPAK® GAS BURNER SYSTEMS

•A complete “packaged burner” system for maximum efficiency

•Pre-assembled system includes:

–High turndown Model “400” OVENPAK® Burner

–Completely assembled and pre-wired pipe train package

•Fast and easy installation with your choice of mounting options:

–Arranged for mounting onto your existing duct;

–Or mounted by MAXON in a pre-fabricated combustion heater/duct

•Reduce your fabrication time and costly design details

•Easy mounting provided by flanged duct connection joints

•Application flexibility offered by:

–Three duct sizes

–Five capacity options

–Optional return/inlet duct opening positions

•Discharge air volumes up to 12,000 SCFM

•Handles discharge air temperatures up to 600°F (316°C)

DESIGN AND APPLICATION DETAILS

OVENPAK® Burners are nozzle-mixing gas burners for many industrial direct-fired applications where clean combustion and high turndown are required. They are simple and versatile for use on a variety of heating applications.

The Model “400” OVENPAK® Burner includes a combustion air blower with nonsparking paddle wheel-type impeller, pilot, spark ignitor, stainless steel discharge sleeve, mixing cone, self-contained internal air and gas proportioning valves, and provision for your flame safeguard sensor.

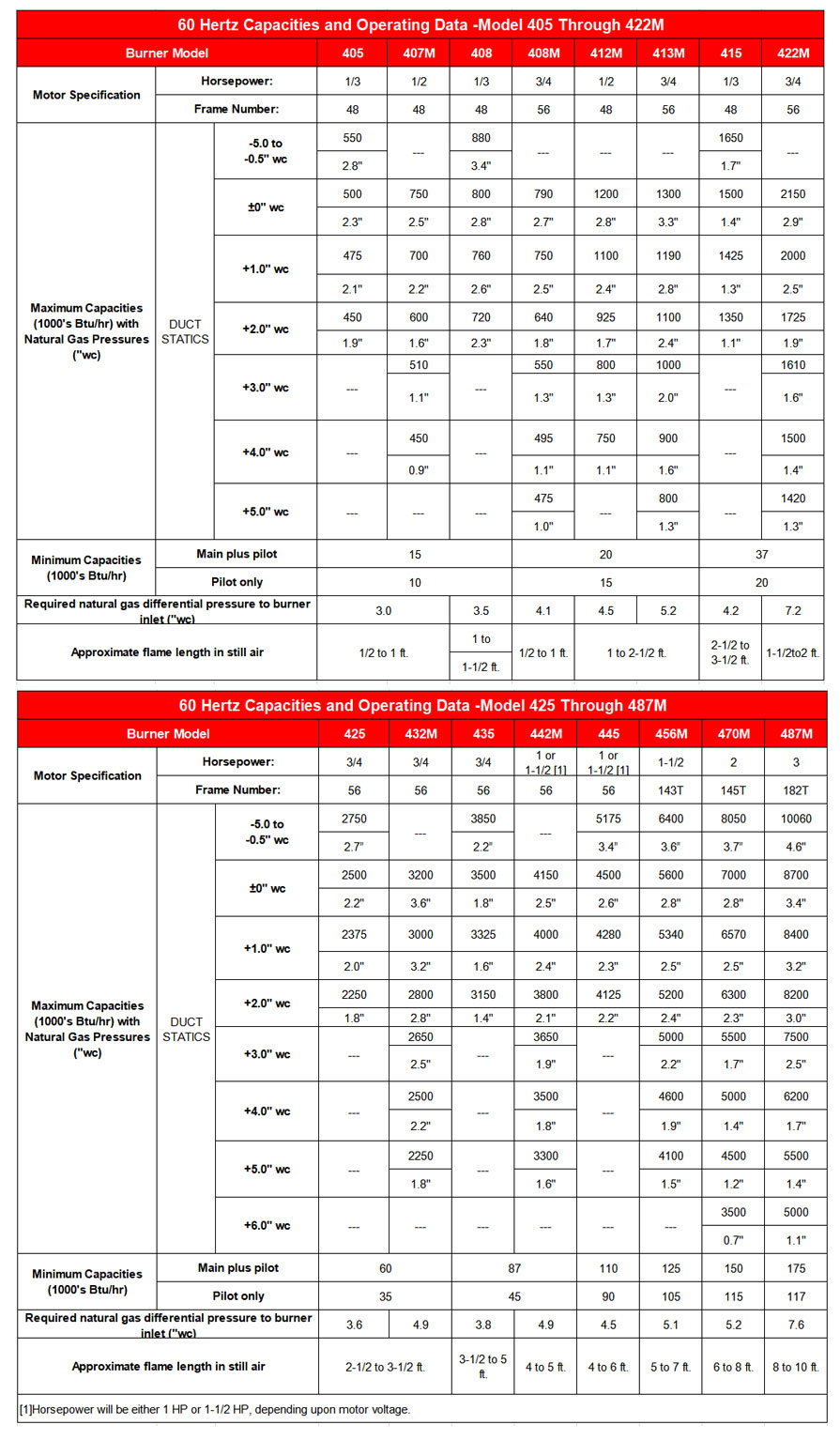

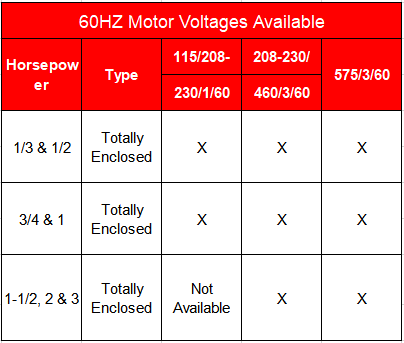

60 Hz Motor Voltages Available

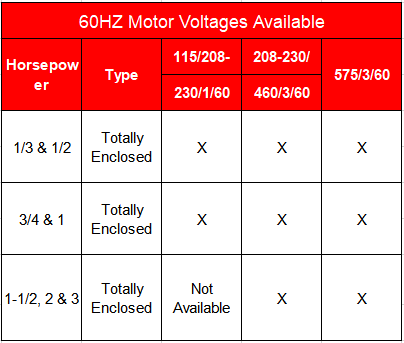

60 Hz Motor Voltages Available

Maximum capacity of Model “400” OVENPAK® Burner is affected by the static pressure within the combustion chamber. Data shown assumes firing in the open, or into an airstream with enough oxygen to complete the combustion process. If burner is fired into an oxygen- starved chamber or airstream, capacities may be reduced as much as 25-30%. Do not attempt to operate beyond the duct static pressure range shown. For higher back pressure applications, select from Model “BNEB” OVENPAK® Burner options.

All gas pressures are differential pressures and are measured at the gas pressure test connection on the backplate of each OVENPAK® Burner. Differential pressures shown are approximate.