Description of Heavy Oil Burner BNH Model 75/100/120F:

Heavy oil burner is a combustion machine specially designed for heavy oil with high viscosity and poor atomization performance to improve the combustion performance of heavy oil.The fuel for heavy oil burners usually uses some oil with high viscosity and poor fluidity, such as crude oil extracts, tire oil, pyrolysis oil, etc.

Features of Heavy Oil Burner BNH Model 75/100/120F:

1. Heavy oil burner.

2. Two-stage operation (high/low flame).

3. High pressure mechanical atomisation of fuel using nozzle.

4. Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

5. Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler.

6. Minimum and maximum air flow regulation for first and second stage by means of electric servomotor with pause closure of gate to prevent any heat dispersion to flue.

7. With the fuel pre-heater which installed with thermometer and adjustable temperature controller.

8. One flange and one insulating seal for boiler fastening.

9. Combustion air intake with air flow adjustment device.

10. Adjustable blast-pipe with stainless steel nozzle and deflector disk in steel.

11. Three-phase electric motor to run fan and pump.

12. Flame presence check by photo resistance.

13. Electrical plant protection rating lp40.

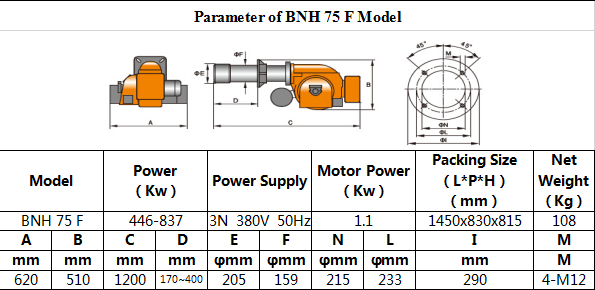

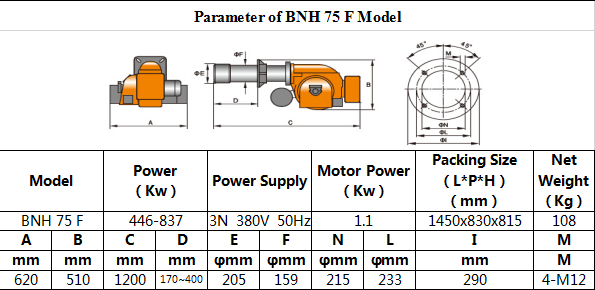

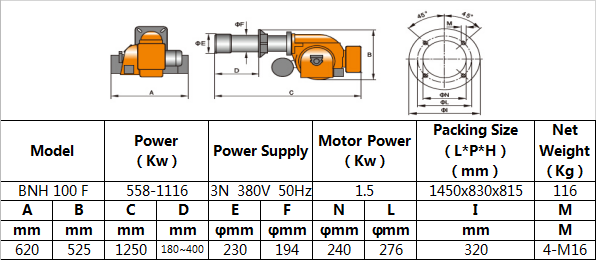

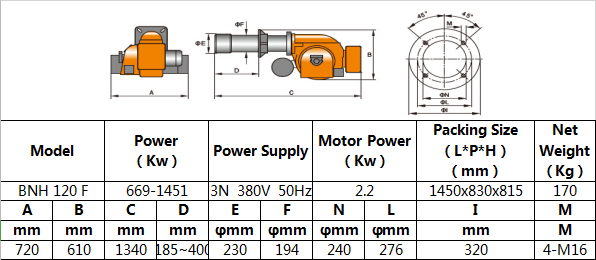

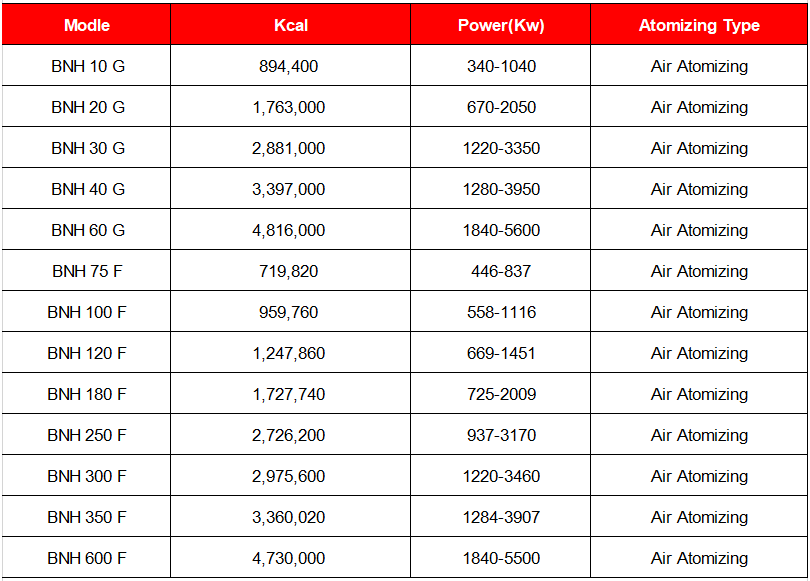

Parameters of Heavy oil burner series:

Boiler heavy oil burner application:

Mainly suitable for oil-fired boilers, industrial boilers, water heaters, steam boilers;

Food machinery hot air rotary furnaces, coating equipment, paint lines, paint stripping furnaces, textile machinery singeing machines, ironing equipment;

Road construction machinery; industrial kilns, ceramics All combustion heat equipment, such as equipment, has a very wide range of applications.