1.Gas-fired burner.

2.One/Two-stage working.

3.Air-gas mixing at blast-pipe.

4.Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

5.Maintenance facilitated by the fact that the atomisation unit can be removed without having to remove the burner from the boiler.

6.Single stage manual flow adjustment.

7.Two stage Minimum and maximum air flow regulation for first and second stage by means of electric servomotor with pause closure of gate to prevent any heat dispersion to flue.

8.One flange and one insulating seal for boiler fastening.

9. Combustion air intake with air flow adjustment device.10. Sliding boiler coupling flange to adapt to head protrusion of the various types of boilers.

9.Monophase electric motor to run fan.

10.Flame presence check by ionisation electrode.

11.Electrical plant protection rating IP40.

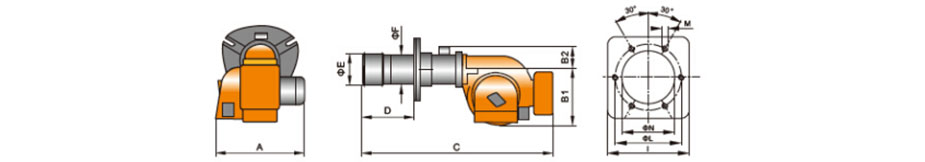

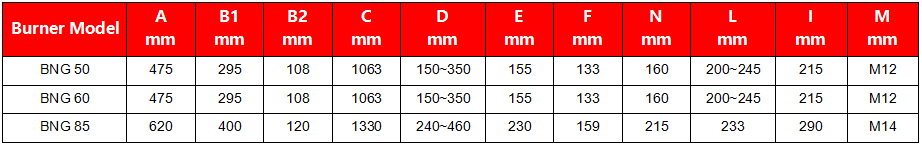

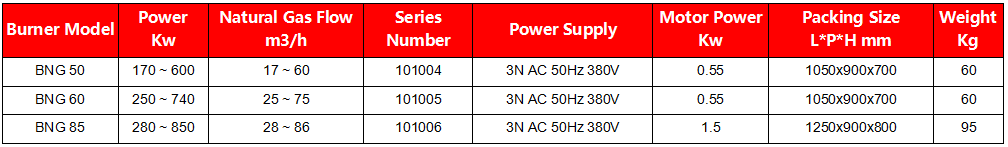

The Data of Gas Burners BNG 50/60/85

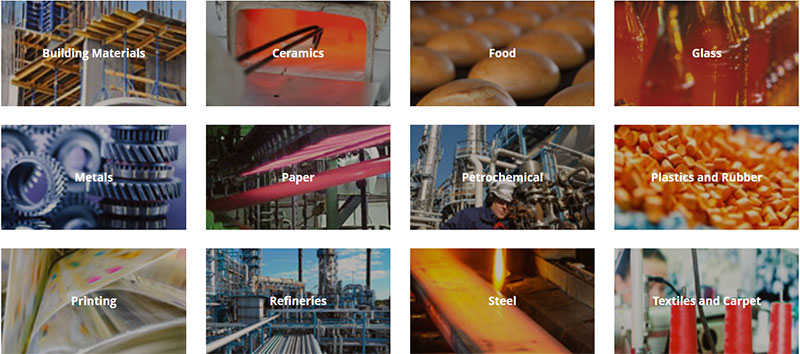

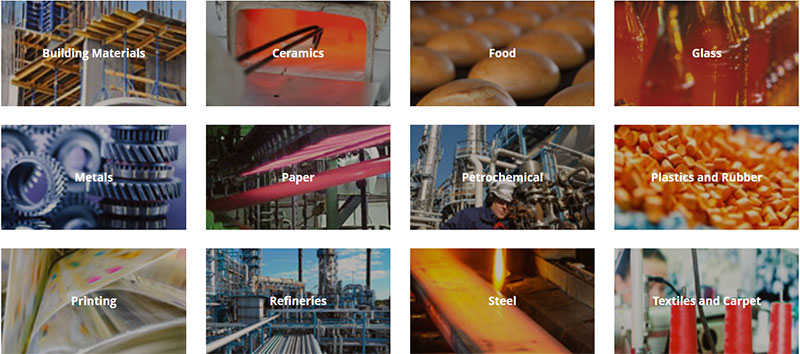

Our experience in nearly all types of industrial burner applications ensures you of quality products that meet the rigorous demands of your operation.

• Ovens

• Ovens

• Air heaters

• Textile machines

• Food, paper & pulp, and plastic processing

• Paper drying

• Fume incineration

• Metal industry

• Low temperature metal finishing