Introduction

In the industrial sector, efficiency and reliability are paramount when it comes to heating systems.

The choice of burner plays a crucial role in the overall performance of an industrial boiler.

High-quality gas and LPG compact burnershave become increasingly popular due to their efficiency,

compact design, and environmental benefits. This article explores the advantages,

features, and applications of these advanced burners in industrial settings.

Advantages of High-Quality Gas/LPG Compact Burners

1. Efficiency

High-quality gas and LPG burners are designed to achieve optimal combustion, ensuring that fuel is used effectively.

This results in higher thermal efficiency and lower fuel consumption, which translates to cost savings for businesses.

With advanced control systems, these burners can adjust to varying load demands, maintaining efficiency across a wide range of operating conditions.

2. Compact Design

The compact design of these burners allows for easy installation in limited spaces, making them ideal for various industrial applications.

Their small footprint does not compromise performance, allowing industries to maximize their available space without sacrificing heating capacity.

3. Environmental Benefits

As industries strive to reduce their carbon footprint, high-quality gas and LPG burners offer a cleaner alternative to traditional fuel sources.

They produce lower emissions of harmful pollutants, such as nitrogen oxides (NOx) and carbon monoxide (CO),

contributing to better air quality and compliance with environmental regulations.

4. Versatility

Gas and LPG burners can be used in a variety of applications, including steam generation, hot water production,

and process heating. Their versatility makes them suitable for industries such as food processing, pharmaceuticals, textiles, and manufacturing.

5. Safety Features

Modern compact burners come equipped with advanced safety features, including flame detection systems,

pressure monitoring, and automatic shut-off mechanisms.

These features enhance operational safety, protecting both personnel and equipment from potential hazards.

Key Features

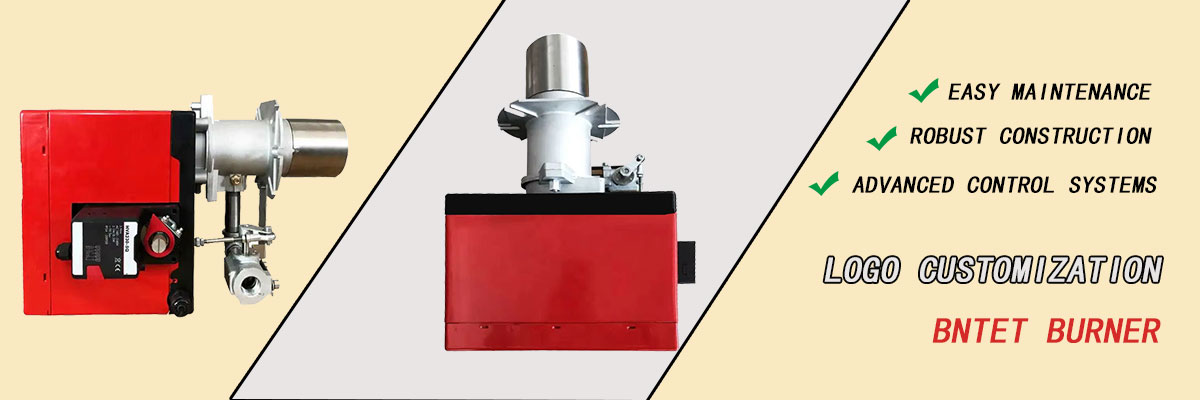

1. Advanced Control Systems

High-quality burners incorporate sophisticated control systems that allow for precise monitoring and adjustment of combustion parameters.

This ensures optimal performance and efficiency, reducing the risk of operational issues.

2. Robust Construction

Built with durable materials, these burners are designed to withstand harsh industrial environments.

Their robust construction ensures longevity and reliability, minimizing maintenance requirements and downtime.

3. Easy Maintenance

The design of compact burners facilitates easy access for maintenance and servicing.

This reduces the time and cost associated with upkeep, allowing businesses to focus on their core operations.

Applications

High-quality gas and LPG compact burners are widely used in various industrial applications, including:

Boilers: Providing efficient heating for steam and hot water generation.

Dryers: Used in industries such as textiles and food processing for drying products.

Heating Systems: Supporting process heating in manufacturing and chemical industries.

Incinerators: Employed in waste management to ensure complete combustion of waste materials.

Conclusion

High-quality gas and LPG compact burners are essential components in modern industrial heating systems.

Their efficiency, compact design, and environmental benefits make them an attractive choice for a wide range of applications.

As industries continue to prioritize sustainability and operational efficiency,

investing in advanced burner technology is a strategic move that can lead to significant long-term benefits.

By choosing the right burner, businesses can enhance their productivity while contributing to a cleaner and more sustainable future.