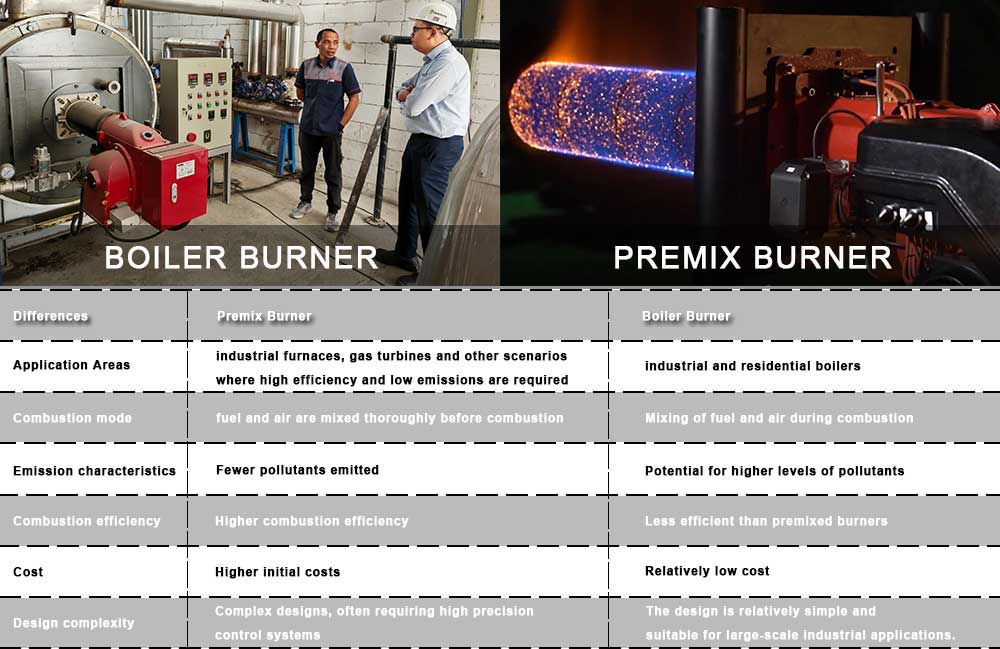

Here are five key differences between premix burners and boiler burners:

1. Fuel-Air Mixing

Premix Burners: Fuel and air are mixed before entering the combustion chamber,

resulting in a homogeneous mixture that promotes efficient combustion.

Boiler Burners: Typically mix fuel and air in the combustion chamber itself,

which can lead to less uniform combustion and potentially higher emissions.

2. Combustion Efficiency

Premix Burners: Generally achieve higher combustion efficiency due to better fuel-air mixing,

leading to more complete combustion and lower emissions.

Boiler Burners: May have lower combustion efficiency compared to premix burners,

especially if the mixing is not optimal, which can result in unburned fuel and higher emissions.

3. Flame Characteristics

Premix Burners: Produce a more stable and controlled flame, often with a lower flame temperature, reducing the risk of NOx formation.

Boiler Burners: Flame characteristics can vary widely depending on design and operation,

and they may produce higher flame temperatures, increasing the potential for NOx emissions.

4. Application and Design

Premix Burners: Commonly used in applications requiring precise control over combustion conditions,

such as in residential heating or small industrial applications.

Boiler Burners: Designed for larger industrial or commercial boilers,

where high thermal loads and varying operational conditions are common.

5. Emissions Control

Premix Burners: Typically equipped with advanced emissions control technologies due to their high efficiency and low emissions profile.

Boiler Burners: May require additional emissions control systems (like SCR or SNCR) to meet regulatory standards,

especially if they operate with lower efficiency.

Summary

In summary, premix burners excel in efficiency and emissions control due to their pre-mixed fuel-air approach,

while boiler burners are more versatile for larger applications but may require additional measures to optimize combustion and reduce emissions.