Introduction of industrial heating drying burner:

When the fire is burning, the temperature keeps increasing. It is this high temperature that makes production easier. Steel production requires the high temperature of fire to make steel, and life requires the high temperature of fire to cook food. The high temperature of fire is more useful, but dangerous. The performance is also very high. To reduce the risk of OR, it is necessary to strengthen the fire control. The traditional wood fire may have unstable fire control, but the current gas life has a relatively stable and safe fire control. The best tool to control the gas fire source is the Bona burner. The size of the fire source can be controlled through the control of the gas delivery. There are many types of burners, including gas delivery, coal powder and fuel oil, and gas delivery. Burners are generally used for domestic purposes, while pulverized coal and oil burners are commonly used in industrial burners. Industrial burners can generate a relatively large fire source, so in terms of safety, industrial burners have to do more than ordinary burners. Security measures.

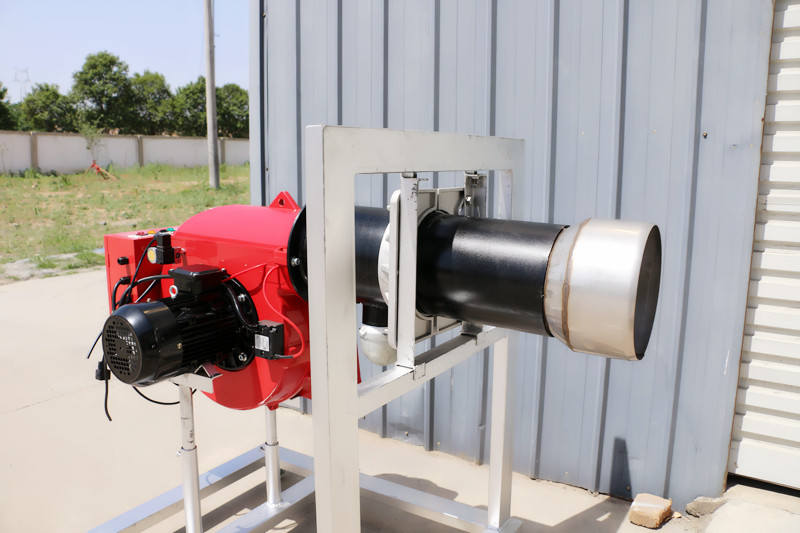

Industrial burners used in industrial raw food are composed of multiple systems. The first is the transportation system. The transportation system is a pipeline for the transportation of pulverized coal and fuel oil. This pipeline must have increased sealing and quality, and it will be carried out for a long time during transportation. The pipes of industrial burners are not allowed to leak, otherwise industrial production will be very dangerous. Ignition system, here is the place where the fire source is provided, but this kind of source is relatively small and can only play the role of ignition. The detection system detects the fuel transportation and the size of the fire. Only the safe operation of the detection system can ensure the safe use of industrial burners.