The working process of nature gas / marsh gas monoblock boiler burner:

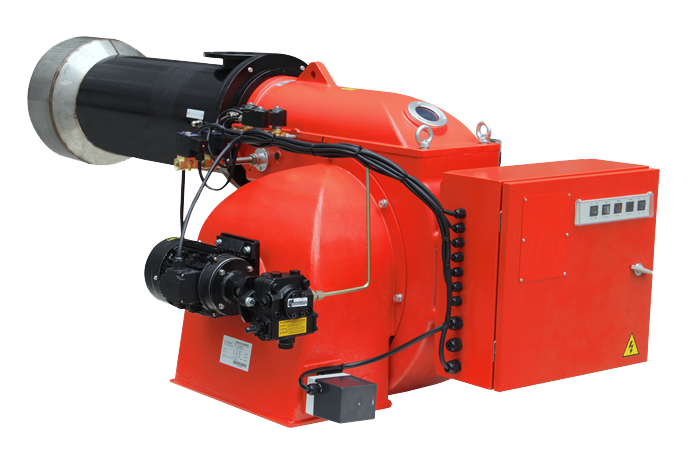

As a kind of mechanical and electrical integration equipment with a high degree of automation, the burner can be divided into five major systems from its functions: air supply system, ignition system, monitoring system, fuel system, and electronic control system. Burners usually include gas burners, light oil burners, heavy oil burners, biomass burners, etc.The following mainly explains the working process of the gas burner. Only by understanding the working engineering of the burner can we perform maintenance and troubleshooting when the burner fails.

Take the proportional gas burner as an example to explain to you, its working process has four stages: preparation stage, pre-purge stage, ignition stage and normal combustion stage.

Preparation stage: After the program controller is powered on, the internal program self-check starts. At the same time, the servo motor drives the air door to the closed state. After the program self-check is completed, it is in the standby state. When the thermostat, the gas pressure switch is too high or the low, the steam pressure of the steam boiler When the limit switch such as the switch allows, the programmer starts to start and enters the pre-purge phase. If the solenoid valve group is equipped with a leakage detection system, the system will first perform valve leakage detection when the above-mentioned limit switch permits, and then enter the pre-purge stage after passing the detection.

Pre-purging stage: The servo motor drives the air door to the high-fire opening state, and the fan motor starts at the same time, and the air is blown in for 13 seconds to blow in the air for pre-purging. Depending on the program controller, after purging for about 20-40 seconds, The servo motor drives the damper to the ignition opening state, ready for ignition. Throughout the pre-purge stage, the air pressure switch measures the air pressure. Only when the air pressure is maintained at a sufficiently high level can the pre-purge process continue.

Ignition stage: After the servo motor drives the air door to the ignition opening state, the ignition transformer works and outputs high voltage to the ignition electrode to generate ignition sparks. After about 3 seconds, the programmer sends power to the safety solenoid valve and the proportional solenoid valve After the valve is opened, the gas reaches the combustion head, mixes with the air provided by the fan, and is then ignited. Within 2 seconds after the valve is opened, the ionization electrode should detect the presence of flame. Only in this way, the programmer will continue the following procedure, otherwise, the programmer will lock and disconnect the solenoid valve to stop the gas supply and alarm at the same time. (Ignite during the motor start time)

Normal combustion stage: After a few seconds of normal ignition and stable combustion, the servo motor drives the damper to the high-fire opening state, (the fuel pump of the fuel engine opens to start fuel injection) At the same time, the servo motor of the proportional gas control valve cuts in and changes according to the air pressure. The gas pressure after the gas valve is adjusted with the furnace back pressure to adjust the gas volume to achieve the purpose of stable and efficient combustion. After that, the burner will automatically switch between large and small fires and shut down according to the requirements of each limit switch.

In addition, during the entire combustion process, the ionization electrode and the air pressure switch monitor the burner.