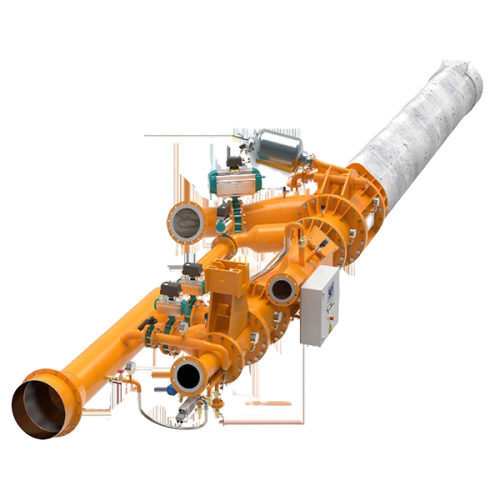

1) The arrangement form of each channel: For three-channel burners, the arrangement of each channel is basically the same by manufacturers, that is, the external axial flow air, coal air and swirling air are discharged from the outside to the inside, and an ignition (oil gun) channel is added in the middle.In general, the center channel is not used, usually it is blocked.For four-channel burners, the arrangement of each channel varies from manufacturer to manufacturer. The central channel is generally used as the ignition channel, the outermost channel is the outer axial flow duct, and the arrangement of other multi-channel burners is different.

2) Features of various arrangement forms of multi-channel burners.The common characteristics of lifting is that the external axial flow fan mainly has two functions, one is the "package" flame, the second is the coil suction secondary high temperature air;The functions of swirl wind and inner axial flow wind are mainly to help strengthen the backflow from north to outside and "shatter" the coal powder and enhance the contact between coal particles and air.

The first arrangement is characterized by the premixing of the two at the outlet of the swirling wind and the outer axial flow, so that the axial flow tends to the center when it is mixed, and it has a strong penetrating power to the swirling wind, so that the primary wind maintains a high swirling strength and is conducive to the roll-suction and backflow of the combustion flue gas.The hesitant coal channel is surrounded by the swirling wind and axial flow wind, so as to appropriately increase the CO2 concentration at the root of the flame and reduce the O2 content. Under the condition of not affecting the ignition rate, the lower temperature level can be maintained and the thermal NOX production can be effectively inhibited.The central wind does not offset the residual negative pressure generated by the high cyclone intensity at the flame root, and the unignited coal is sucked up and the pressurized chamber nozzle outlet causes tempering, affecting the flame stability.