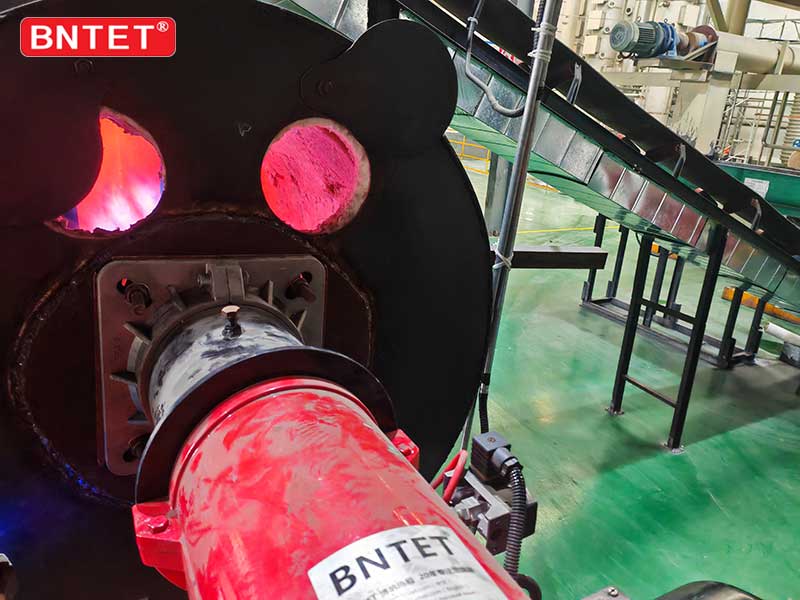

This case is mainly about the application of gas burners in dryers. The gas burners provide the heat required by the machine through combustion and dry the products. Gas burners use natural gas and other gas as fuel, which is much more environmentally friendly than traditional fuel coal and can greatly reduce air pollution caused by incomplete combustion.

The main advantages of the gas burner used this time are:

1. One-stage/two-stage work. -Can control flame size

2. The air and gas at the blast pipe are mixed. - Let the fuel burn more fully

3. Able to obtain the best combustion value by adjusting the combustion air and blast pipe.

4. The atomization device can be removed without removing the burner from the boiler, thus facilitating maintenance.

5. Single-stage manual flow adjustment.

6. The two stages adjust the minimum and maximum airflow of the first and second stages through electric servo motors, and pause to close the gate to prevent any heat from spreading to the flue.

7. The boiler is fastened with a flange and an insulating seal.

8. The combustion air inlet is equipped with an air volume adjustment device.

9. Sliding boiler connecting flange, adaptable to various boiler head convexities.

10. Single-phase motor drives the fan.

11. Check for flame presence via ionization electrode.

12. Electrical equipment protection level IP40.