Rotary Kiln

Description of Rotary Kiln

Rotary kiln refers to rotary calcining kiln (commonly known as rotary kiln), which belongs to building materials equipment category. Rotary kilns can be divided into cement kilns, metallurgical chemical kilns and lime kilns according to different materials. Cement kilns are mainly used for calcination of cement clinker, divided into two categories: dry production cement kilns and wet production cement kilns. Metallurgical chemical kilns are mainly used for the magnetic roasting of lean iron ore in the metallurgical industry; oxidation roasting of chromium and nickel iron ore; roasting high alumina bauxite ore in refractory plants and roasting clinker and aluminum hydroxide in aluminum plants; roasting chrome ore in chemical plants And minerals such as chrome ore powder. Lime kiln (i.e. active lime kiln) is used to roast active lime and light-burned dolomite used in steel plants and ferroalloy plants. Rotary kilns are divided into variable diameter rotary kilns and through-diameter rotary kilns according to their appearance. According to their uses, they can be divided into cement rotary kilns, ceramsite sand rotary kilns, kaolin rotary kilns, lime rotary kilns, etc., according to different energy supply effects. It is a gas-fired rotary kiln, a coal-fired rotary kiln, and a mixed-fuel rotary kiln.Rotary Kiln Work Principle:

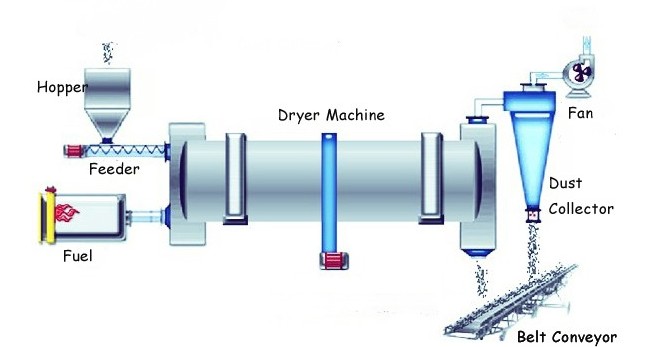

Based on the structure of a traditional rotary dryer, steam tube rotary dryer/ calcinator is equipped with some steam heating tubes inside of the dryer. The heating tubes run through the dryer with pattern of 1 to 5 concentric circle(s), supplying heat needed by drying process. The heating tubes rotate along with the rotary drum. The material entrained in calcinator is lifted and agitated by the heating tubes in the rotary drum. Being dehydrated/calcined by heat from the tubes, the product will move by inclination of the dryer/calcinator from the upper end to the lower one and discharged from the outlet at the lower end. The vaporized water will be vented by fans or in way of natural ventilation. As for the organic solvent, it can be recovered by airtight steam tube rotary dryer/calcinator. The circulation of inert gas can be used against explosion.

Product Characteristics:

1. large heat transfer area, high thermal efficiency

2. high handling ability, suitable for the continuous operation

3. low drying temperature, simple operation, easy to use

4. The gas is only used to transfer the volatile component, little amount of gas is used, and the dust removal system is simple.

5. High efficiency of the airtight system, extremely suitable for the recycling of organic solvents such as ethane.

Material to be dried:

1. Applicable for drying big particles, heavy particles in chemical, mining, and metallurgy, such as mining area, cinder of blast furnace, coal, powder of metal, phosphate fertilizer and thiamine.

2. For drying the powder or particles with special requirements, such as H P foaming blowing agent, residule of alcohol, light calcium carbonate, active clay, magnetic powder , graphite, and residue of medicine.

3. For materials to be dried under low temperature and large lot continuous production.

Our rotary kilns have been successfully applied in the following industry:

▲ Rotary kilns for the cement industry

▲ Rotary kilns for lime calcination

▲ Rotary kilns for lightweight aggregate

▲ Rotary kilns for LECA

▲ Rotary kiln incinerator

▲ Rotary kilns for hazardous waste incineration

▲ Rotary kilns for medical waste incineration

▲ Rotary kilns for iron ore pelletizing

▲ Rotary kilns for active carbon producing

▲ Rotary kilns for activated carbon regeneration

▲ Rotary kilns for burning of petroleum coke

▲ Rotary kilns for burning of zinc material

▲ Rotary kiln for α-alumina

▲ Rotary kilns for oil fracturing proppant

▲ Rotary kilns for lime recovery

▲ Rotary kilns for sintering and burning of magnesite and dolomite

▲ Rotary kilns for direct reduction and burning of chromium ores

▲ Rotary kilns for reduction processes of metallized pellets

▲ Rotary kilns for pre-reduction of nickel and manganese ores

▲ Rotary kilns for mining and smelting industry

▲ Rotary kilns for burning of aluminium and bauxite

▲ Rotary kilns for concentration and burning of soda and phosphates

▲ Rotary kilns for treatment of secondary mineral raw materials

we can use gas burner, light oil burner.

we can use gas burner, light oil burner.