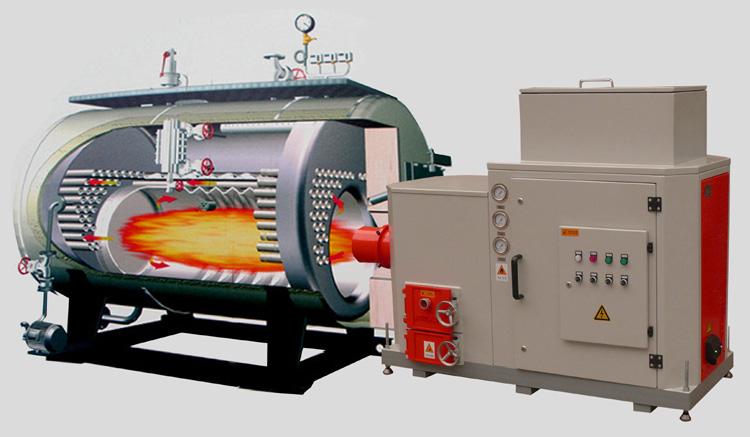

Biomass burner uses biomass wood pellets as fuel, and the biomass pellets are sent into the combustion chamber for direct combustion through an automatic feeding device, and the heat energy after combustion can be directly supplied to the boiler, powder coating, die casting, clothing, hotel, heat treatment and other heating equipment. The product adopts semi-gasified composite combustion technology, which has the characteristics of reasonable structure, automatic feeding, high thermal efficiency, full combustion, low sulfur content, no pollution, low emissions, simple and convenient installation, and small space occupation. The operating cost of biomass burners is low, which can save 30%-60% of operating costs compared to fuel oil/gas burners.

Advantages of biomass burner:

1. High-efficiency and energy-saving: Renewable biomass pellet fuel is used as energy source, the using cost is low, and the operating cost is 30%-60% lower than that of fuel oil/gas.

2. High thermal efficiency: semi-gasified suspension combustion with tangent a swirl flow air distribution design, low temperature staged combustion, burnout rate of more than 98%, and furnace temperature of more than 1200 ℃.

3. Stable and reliable: Micro-positive pressure operation, silo isolation transportation method, no tempering and de-firing phenomenon, has applied for national invention patent.

4. Low-carbon environmental protection: low smoke, sulfur and nitrogen emissions, and nearly zero carbon dioxide emissions, accord with smoke emission requirements.

5. Simple operation: easy installation, automatic feeding, simple operation, less workload, large silo capacity (larger capacity silo can be customized). The feeding can be run for 3-12 hours at a time, only need to fill the bin in time, only one person on duty is OK.

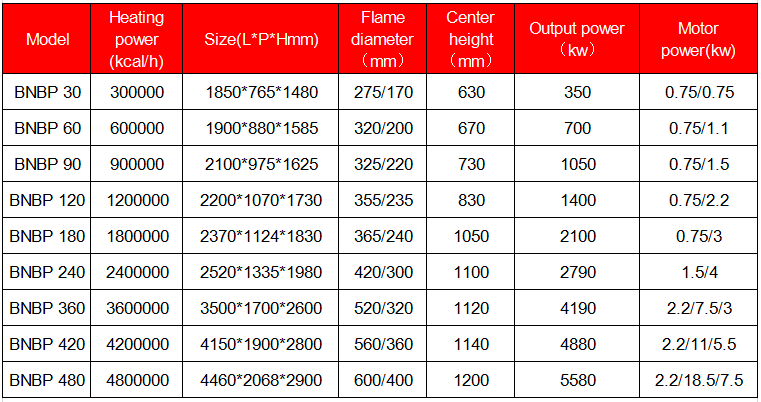

General model configuration parameters:

Application range:

Biomass burners are widely used in spray drying lines, casting heat treatment, annealing furnaces, aluminum rod heating furnaces, clothing, hotels, melting boilers, industrial furnaces, greenhouses, steam boilers, hot water boilers, thermal oil boilers, hot air Furnace, drying equipment, paint, wood, gravel, leather, clothing, ceramics, paper products, food drying equipment, etc., for heating equipment use and energy-saving transformation.